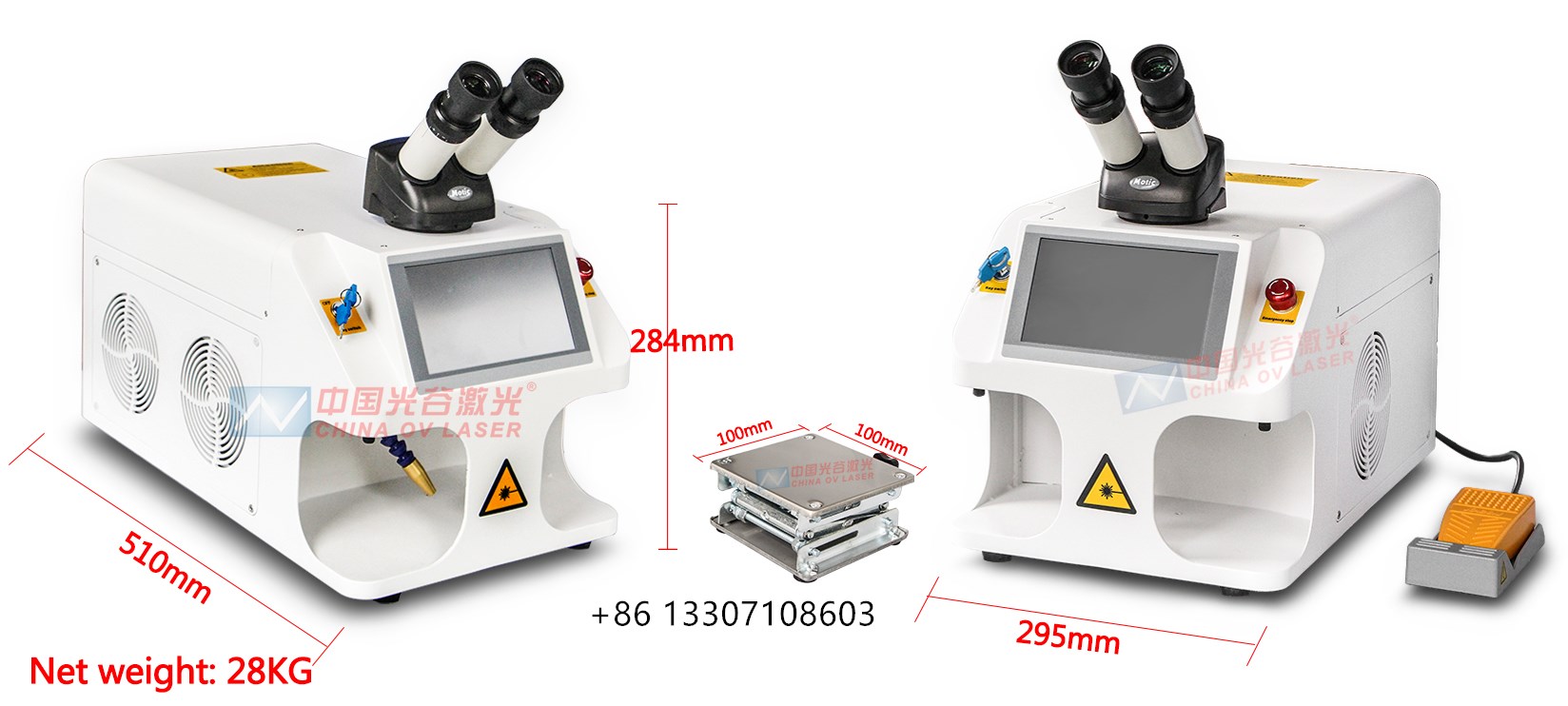

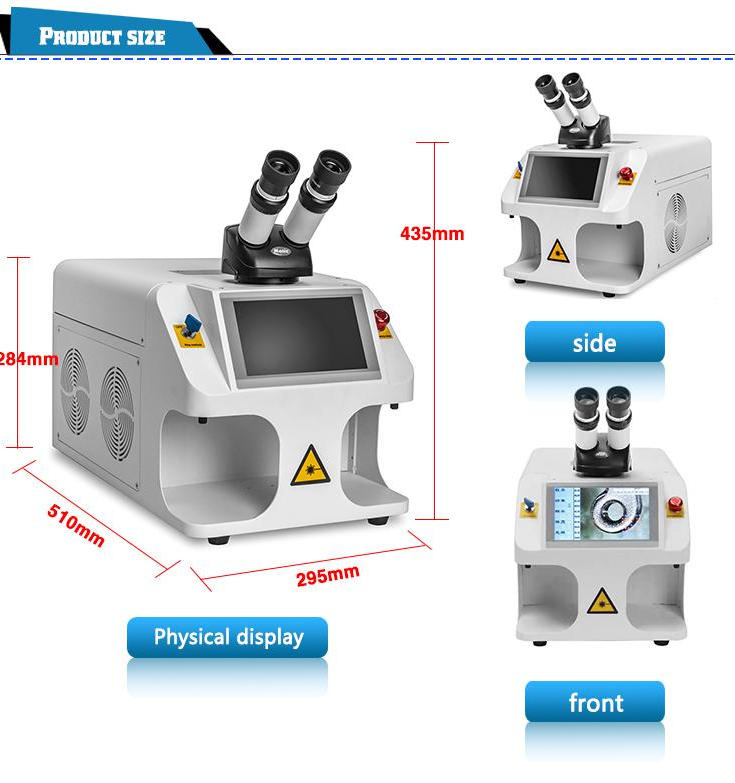

Technical data:

| Product Name | CCD 60W Laser Welding Machine | Host power consumption | ≤2KW |

| Model | OV JW-60 | electricity demand | 220V±5%,50HZ |

| Laser Source | YAG | cooling method | Water circulation air cooling |

| Power | 60W | Machine weight | 28kg |

| Laser Wavelength | 1064um | Ambient temperature | ≤30℃ |

| Maximum laser pulse energy | 40J | Pulse Width | 0.1-10.0ms |

| Pulse frequency | 1.0-15.0KHZ | Language | Chinese, Turkish, Arabic, English, Korean |

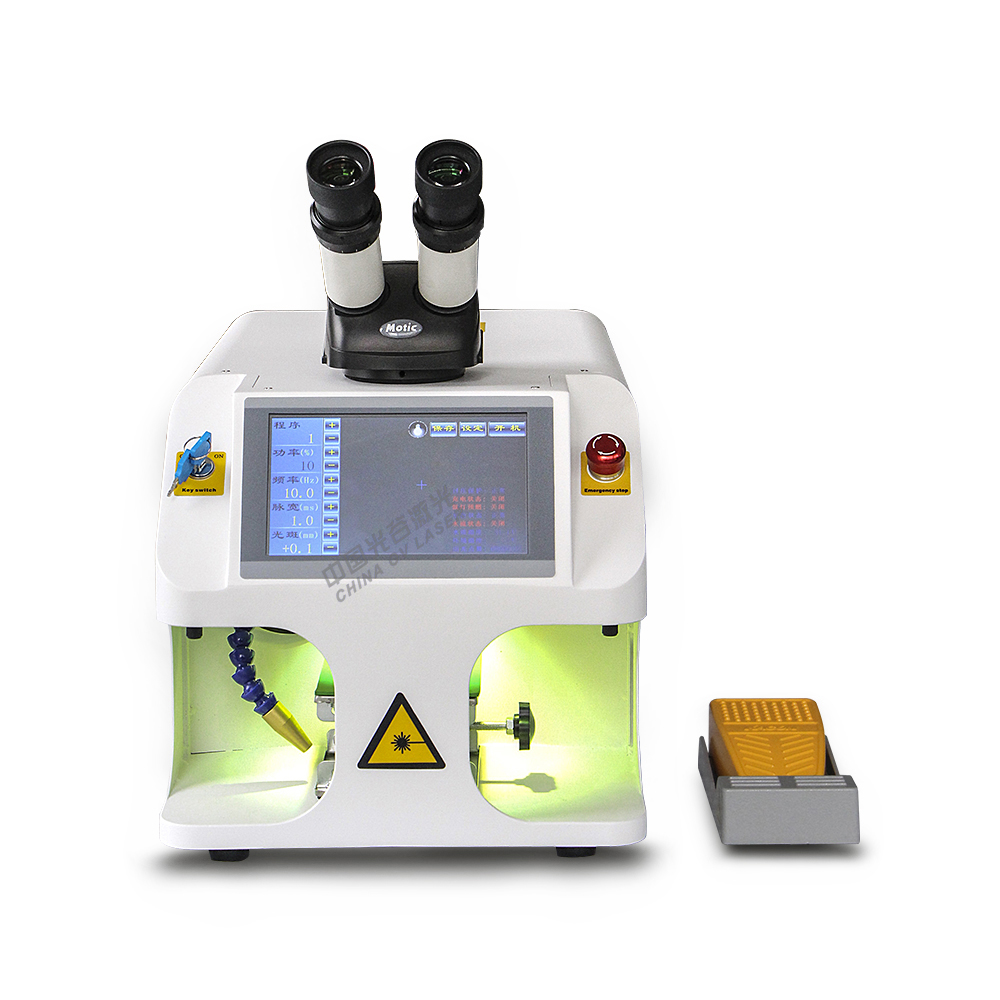

1. Observation system:

The observation system of this jewelry spot welding machine consists of a microscope and a built-in high-definition CCD camera. The user can choose one of them. Both of the two methods can be used as observation methods to clearly observe the welding position of the workpiece, which is convenient for welding.

2. Adjustment of the CCD cross cursor: If the light spot is not in the center of the cross cursor in a very clear position of the CCD camera system, you can change it by clicking the middle position of the four sides of the screen. The position of the cross cursor so that the solder joint is at the center of the cursor

3. Welding operations,

First of all, make sure that the machine has been turned on normally, put the workpiece into the sight range of the observation system, and then slowly move to the clearest position of the observation system.

Point the cursor at the desired welding position, gently step on the foot switch, the machine has laser output for welding.

4. Parameter adjustment, focal length adjustment, after the first welding, the welding effect of the solder joints does not meet the requirements, and the parameters need to be adjusted again, focal length (-3.0-3.0)

Make adjustments until the welding effect meets the requirements, and no adjustments are needed when the welding is repeated later.