Main Features

1)No maintenance and no consumables,dust-free,no chemicals,no pollution.

2)Non-contact cleaning and no damage for substrate

3)Extremely low cleaning cost and High cleaning efficiency.

4)Accurate cleaning for exact position and precise size.

5)Widely applied in flat,curved and three-dimensional surface for work piece of elastic material and plastic with very small and deep holes.

6)Precision positioning, selective cleaning, desired cleaning area can be applied to the workpiece.

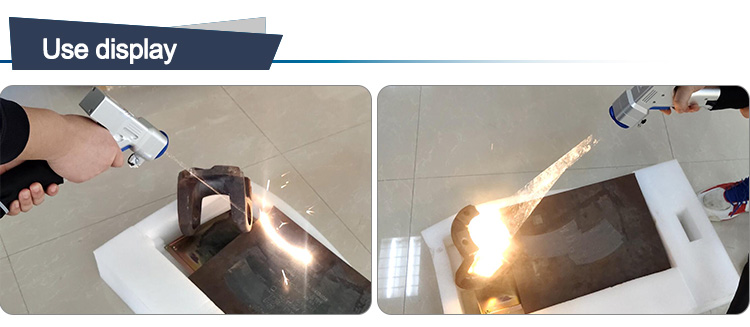

7)Flexible operation for work pieces with complicated geometric construction can be realized by mechanized or hand-held laser cleaning head.

Advantages of laser cleaning

Compared with traditional cleaning methods such as mechanical friction cleaning, chemical corrosion cleaning, liquid solid strong impact cleaning and high-frequency ultrasonic cleaning, laser cleaning has obvious advantages.

1. Advantages of environmental protection: laser cleaning is a "green" cleaning method. It does not need to use any chemical agent and cleaning solution. The cleaned waste is basically solid powder. It is small, easy to store and recyclable. It can easily solve the problem of environmental pollution caused by chemical cleaning.

2. Effect advantages: the traditional cleaning method is often contact cleaning, which has mechanical force on the surface of the cleaned object, damages the surface of the object or the cleaning medium is attached to the surface of the cleaned object,which cannot be removed and produces secondary pollution. The non grinding and non-contact of laser cleaning can solve these problems; Laser cleaning can remove various types of pollutants on the surface of various materials and achieve cleanliness that conventional cleaning cannot achieve. It can also selectively clean the pollutants on the material surface without damaging the material surface.

3. Control advantages: the laser can be transmitted through optical fiber, cooperate with manipulator and robot, conveniently realize long-distance operation, and can clean the parts that are not easy to reach by traditional methods, which can ensure the safety of personnel in some dangerous places.

4. Cost advantage: laser cleaning has high efficiency and saves time; Although the one-time investment in the purchase of laser cleaning system is high in the early stage, the cleaning system can be used stably for a long time and has low operation cost.

More importantly, it can easily realize automatic operation.

Introduction:

OV LASER is the leading provider of laser cleaning solution in China. Supplying 1000watts to 2000 watts laser power for a wide-range of applications. It is easy to install, operate, easy to achieving automation. Plug in power, turn on and start cleaning-without chemicals, media, dust, water. Cleaning with no detergent, no media, no dust, no water. Auto focus, can clean curved surface, gentle cleaning surface. Cleaning resin, oil stain, rust, coating materials, paints on workpiece surface.

Application industry:

Space flight and aviation/ships,automobile/machine manufacturing,mould/hardware tool,food processing/chemical industry,rubber and plastic/tyre,electronics/electrical

equipment,weaponry,building materials/cultural relic,steel structural parts,rail transit/machine tool,etc.

Removal for rust ,oil stain,grease,dirt,resin,mold release,oil paint,coating,weld residue,oxide,production residue,etc.

| SPECIFICATIONS FOR 1000/1500/2000W CLEANING LASERS | |||

| Model | OV-Q1000 | OV-Q1500 | OV-Q2000 |

| Laser Power | 1000W | 1500W | 2000W |

| Laser Wavelength | 1.064μm | 1.064μm | 1.064μm |

| Working Mode | Manual / Auto | Manual / Auto | Manual / Auto |

| Machine Weight | 180KG | 180KG | 190KG |

| Laser Gun Weight | 0.5 KG | 0.5 KG | 0.5 KG |

| Cable Length | 10 Mtrs (can be lengthened) | ||

| Power Supply | 220V Single Phase or 380v±10%, Three Phase | ||

| operate mode | continuation/ modulate | ||

| Cooling method | Water cooling | ||

| Laser Generator | Raycus (Max, JPT are optional) | ||

| Maximum modulation frequency | 20KHZ | ||

https://youtu.be/hDmJCh6WelY